- Email: sxtao@hnjsx.com.cn

- Tel: +86-371-55628659

High automation program: automatic loading, mixing, unloading and transportation, making concrete production effortless.

1. High automation program: automatic loading, mixing, unloading and transportation, making concrete production effortless.

2. Labor saving: 1-2 people can operate, one person can operate, and one person assists in operation.

3. Cost saving: In addition to the labor costs mentioned above, it can also save a lot of material costs.

4. High efficiency: Like a automatic feeding mixer, the output is about 20 cubic meters per hour, and about 500 tons of concrete per day. But if it is manual mixing, the amount of concrete that can be mixed in one hour is limited. Even a mixer is far less efficient than an automatic loading mixer.

5. Strong practicability: Whether it is building roads, bridges and houses, or laying grounds, slopes and foundations, etc., automatic feeding mixer trucks can come in handy. As long as it is a project that requires concrete, its practicality is as high as 100%. In addition, most of the engineering projects are in the mountainous and wild areas, and some even in the plateau grassland.

6.High safety: Because the rear weight is too large, the traditional mixer truck has great safety hazards when climbing. The automatic feeding mixer truck has reasonable design of body structure and counterweight, stable walking and high safety factor.

| Specification parameters: | ||||

| Diesel Engine | type: YN27GBZ total displacement, cylinders 2700cc four-in-line | |||

| Injection: direce injection and mechanical control, water cooling dry air filter | ||||

| Max power:55kw, max torque: 237N.m 2000r/min | ||||

| Electric system | generator:28V-5000WA(18A) Battery:2*2V-60AH(272A) | |||

| Steering | Assisted by double sisplacemnet loading sensor power on steering wheel to turn,articulated steering. | |||

| 4x4 Four wheel Drive | Hydraulic torque converter gearbox, open hydraulic gear oil pump, and reverse gerar control to control working sepped and tracvelling speed. | |||

| Speed | two forward gears, two reverse gears, the first high speed"0-16.5km/h, the second 16.5-32.5km/h, the first low speed, 0-6km/h, the second 6-12km/h | |||

| Axle and Tyre | mini rub reduction axle,with planetary reduction gear, flange connection gearbox, rear alxe, oscillating+-10°, planetary reduction gears on alxes. rtre: 12-16.5-12PR | |||

| Brakes | external disc brake and emergency brake acting on four wheels, independent dual circuit brake and hand control to braking. | |||

| Water system | 24V self-priming volumetric water pump with quick-suction, max flow:90L/min, one water tank. total capacity:175L, visual flow meter, the water intake by manual control. | |||

| Mixing and unloading | double-cone drum with couble-spiral mixing screws and convex bottom,the geometrical volume of drum is 2200L, the rotation speed o fdrum is 15r/min, drum rotation by means of a gear pump hydraulic motor, hand control valve in operating room and the behihd of mixer machine. unloading chute by means of one adjustable handle to control tilt. as S standard configugration, we can provide a chute extension unit. | |||

| Hydraulic system | max flow rate20/40L/min, max pressure 16Mpa, three elements distributor servo-contrilled with multi-fuction joystick. Aluminum heat exchanger for hydraclix oil cooling. Pressurised closed- corcuit intake wuth oil filter replacement from the outside. | |||

| Loading | Loading arm can be equippedn with weighting sensor, loading devide with grab bucket and lifting arms controlled by double-acting hydraulic cylinders, Manual control of the feed inlet has a standard prompt function. capacity:270L times:5 | |||

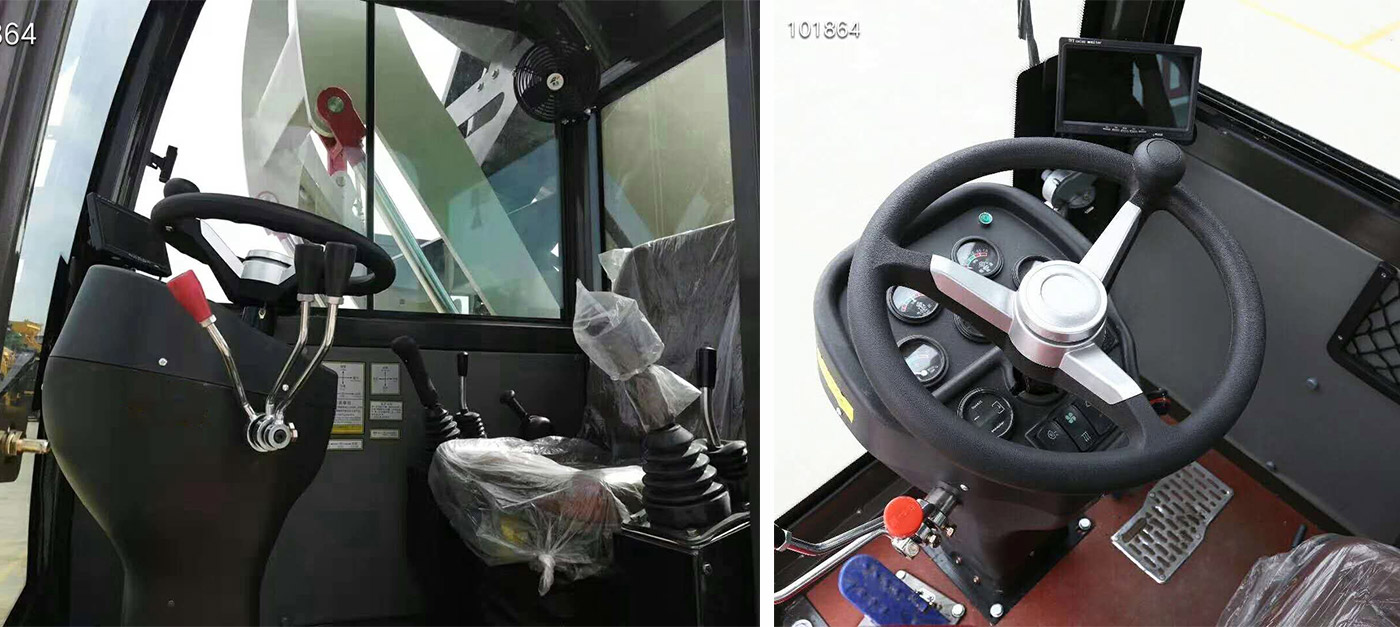

| Cab | closed cab with heating system, tilting front window, humanized seat, flexible suspension and height adjustment are provided. | |||

| Maintenance and oil filling | fuel tank 110L Total hydraulic system capacity:110L engine oil: 16L | |||

| Weight | Operating weight:4500kg Max weight 6900kg Loading carring capacity 2400kg | |||

| Remark | Pictures for reference only, logo and color can be customized. | |||